OK, next trouble to roll into the door. A 2006 Chevy Trailblazer SS 6.0 Liter with a heavy engine knock. Taking this vehicle for a ride, it gave all the classic symptoms of a connecting rod or main bearing fatigue failure.

It had a loud engine knock that got louder as it heated up and was more pronounced under a load. Pulling it into the bay, the noise was coming from the bell housing area on the lift. After separating the flywheel from the torque converter,

the noise was still there (definately coming from the engine). As this engine has the all-wheel drive

differential going through the oil pan and takes 16.8 hours warranty time to R&R, I decided to pull the tranny to make sure it wasn't a cracked flywheel or something silly like that. After this was done, flywheel looks good,

time to pull the engine! Pulling this bear out, sure enough, it has a completely spun #7 main bearing and a few other bearings showing signs of contact stress fatigue. The pictures show the progress . .

A multitude of things removed, getting ready to remove engine |

Dead stall and four benches will eventually be filled with parts |

Monstrous 6.0 Liter engine coming out, this thing sure fills the engine compartment! |

Engine hanging, you can see AWD differential bolted through engine oil pan |

Empty engine compartment |

On engine stand, differential, oil pan and baffle removed |

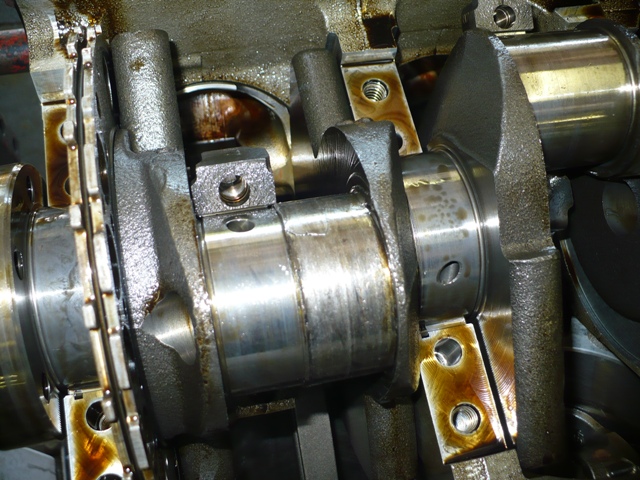

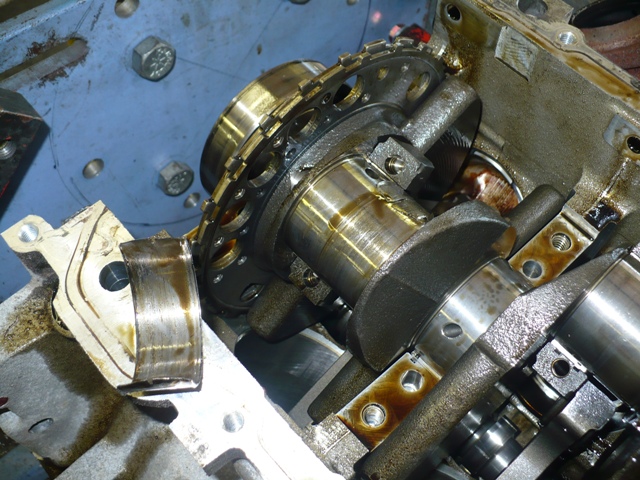

#7 spun rod bearing |

Another view of damage, paper thin bearing |

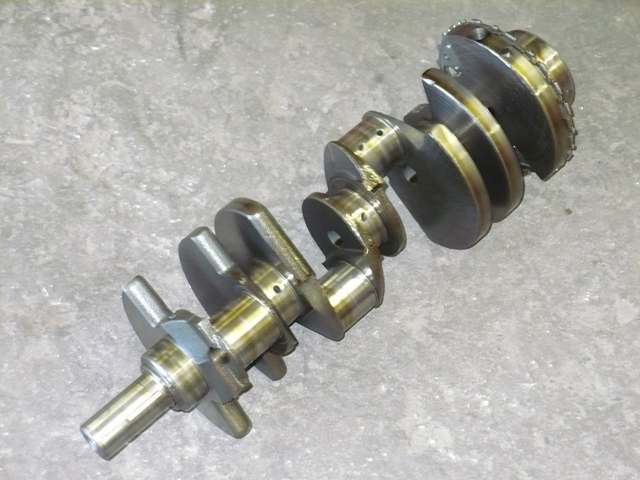

crankshaft removed |

Old crank headed for the scrap yard! |

The old crank and all bearings were then removed. I cleaned all debris, installed new main bearings, installed crankshaft, installed all rod bearings and clearanced them also. There are only standard bearings available stock, but

all clearances were between 0.002 in and 0.0008 in. The front timing chain and gears were installed. The oil pump was taken apart, cleaned, and checked for wear. Being OK, it was reinstalled and the sump and oil baffle were then

installed. I still need to find one of the nuts for the oil baffle. The problem with doing these big jobs is that you have new and old parts scattered around, things fall into the speedy dry or under benches or in a drawer

in your tool box! You forget which bolts go to what sometimes. I try to keep the bolts with the part they were removed so they can go back together with that same part and throw all the old parts into a box reserved for

old parts (sometimes they have to be saved for warranty proof ). The problem when you lose a nut or bolt working on an engine or transmission is that you don't know if it might have fallen into the open engine or transmission

so it gives peace of mind to account for everything. Vehicle is now done, no problems with job, it's been six months.

New crankshaft, only $700 or so. |

All new main bearings, new rod bearings, clearances checked, timing chain and gears, oil baffle, sump tube and pump back on |

Front and rear cover all cleaned with gaskets |

Special alignment tools in place to align rear cover to crank and oil pan |

Straight-edge to check if alignment is correct |

Tools on to do the same with the front cover |

Kent-Moore special tools, have relief for part where gasket sticks out, well-designed tool |

Oil pan cleaned with all new gaskets |

Oil pan installed along with one side of differential |

Front view |

Water pump, AC compressor, balancer all installed |

Front view, differential and other stuff installed |

Going into truck, flywheel and rear seal in |

In truck |

Transmission going in |

All set, just need to put body sheetmetal back on |