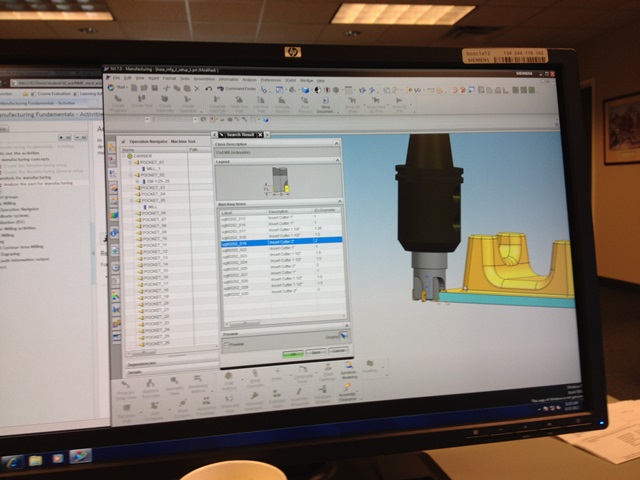

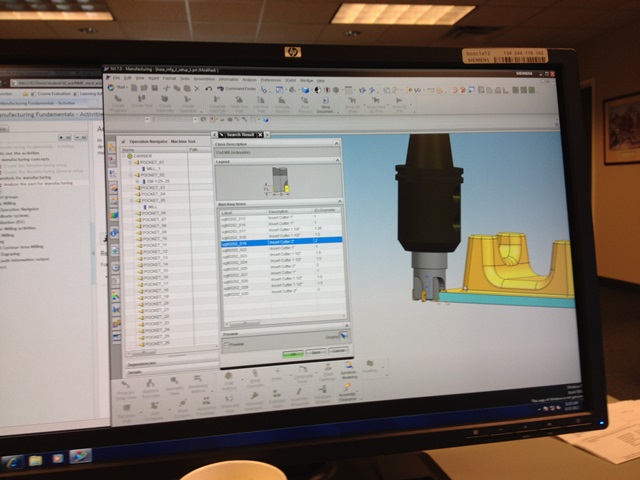

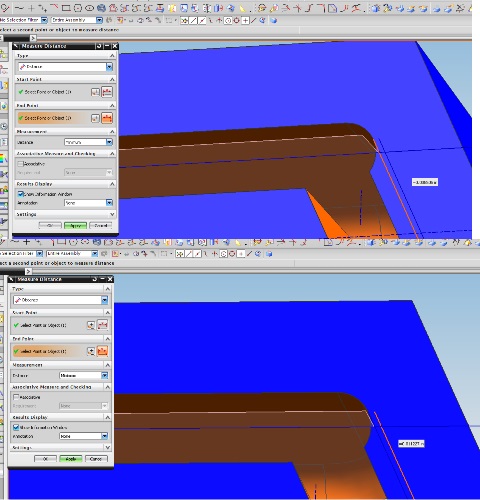

A program being created in Unigraphics NX 6, the actual machine toolpath is being written

<./td>

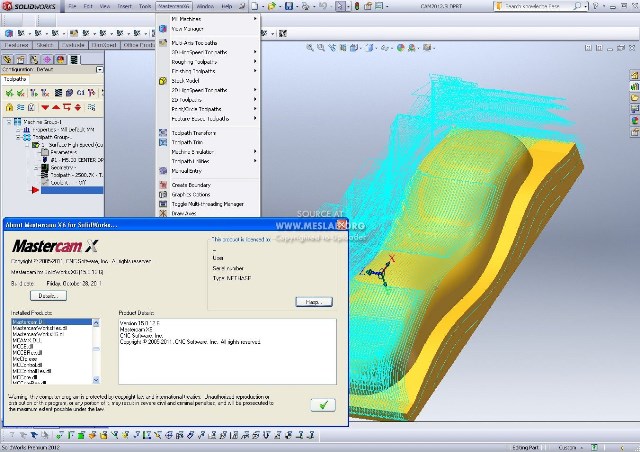

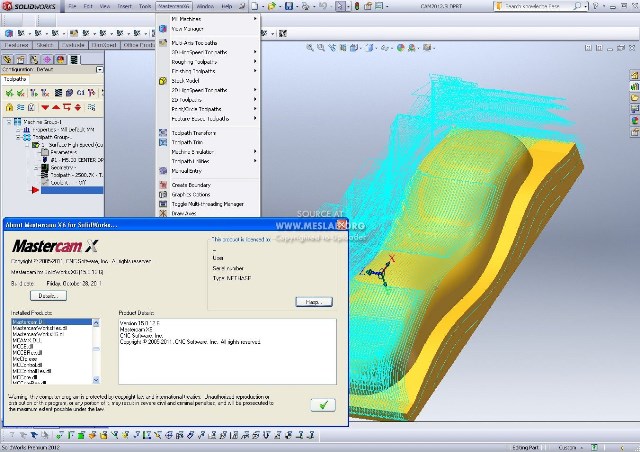

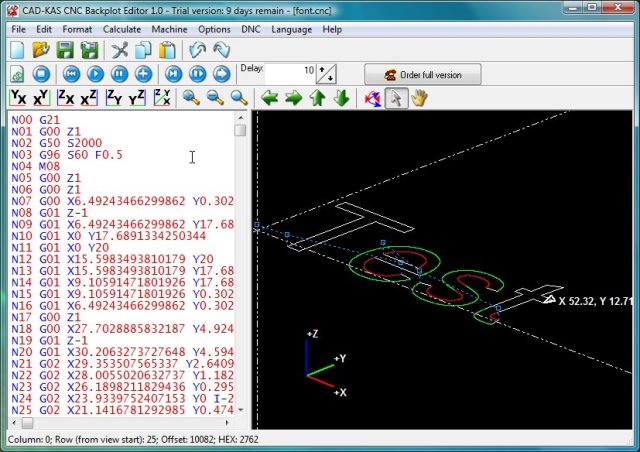

The next step after the operation sheets are written is to write the computer programs that the CNC (Computer Numeric Control) machine will use to actually machine the surfaces in each operation. While every operation doesn't have one, the detailed turning and milling operation will usually have one or two programs. I write these programs using Unigraphics NX. This is done by first loading the CAD model and the fixture (if it has one) of the part into a new CAM file. I then can add comments and generate machine tool paths by creating different reference coordinate systems and picking or creating geometry for the program to use

<./td>

|  |

|

|

The CNC program will just be a series of straight lines, arcs and different feeds and speeds. An initial home coordinate system is chosen and then the machine moves the cutter or part to different points in space. Years ago, this was all done by hand but modern software allows us to generate very complicated tool paths where all three axes are moving in unison to create a detailed surface. As with other pages, images have been taken from simple web searches to protect proprietary code.