This course, Manufacturing 226, teaches us how a CNC Mill or Lathe is both programmed with NC code and also teaches us to use MasterCam X4 CAM software. The beginning of the course taught all the necessary G, M and other

NC code and had us write basic CNC software in Excel and manufacture a few metal projects such as an aluminum block with our initials engraved in it centered on the piece.

The next part of the course teaches us MasterCam X4 CAM software through many hours of practice examples in creating geometry and then creating toolpaths and machining the part virtually in this software.

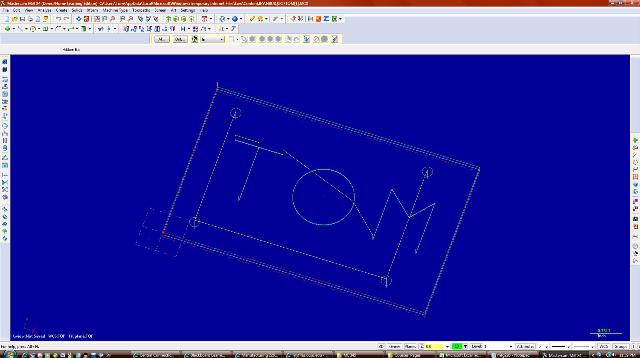

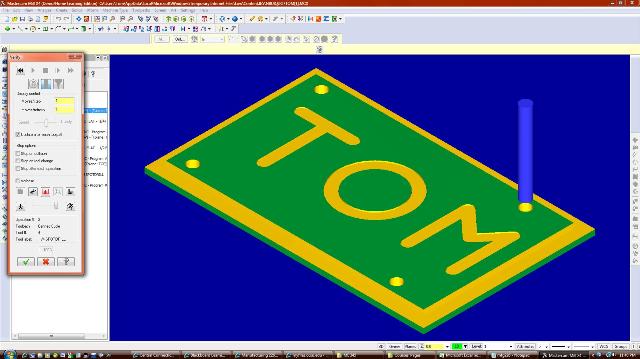

A few example of these are shown below. The first two pictures are the part I machined myself. I first did the initials in the block with handwritten NC code and made the block with the CNC Mill.

I then wrote the Mastercam program with the block with initials, contour around edge and holes.

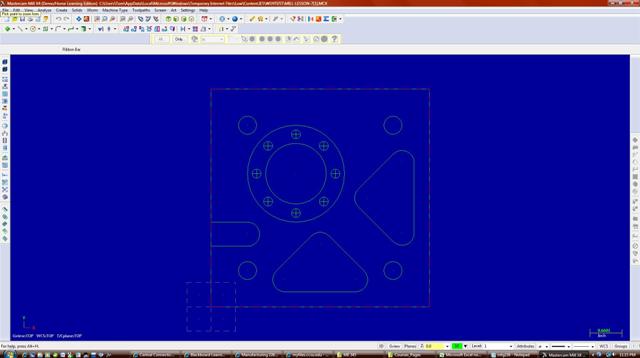

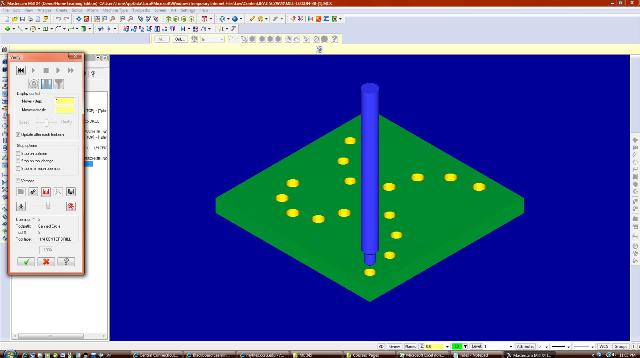

Geometry created with CAD part of the program |

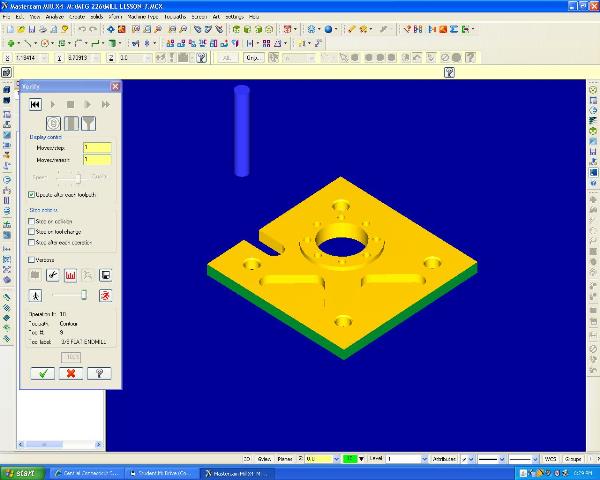

Stock created and tool and tool pattern after machining |

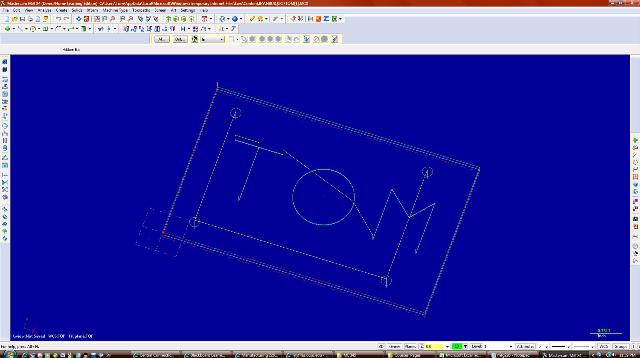

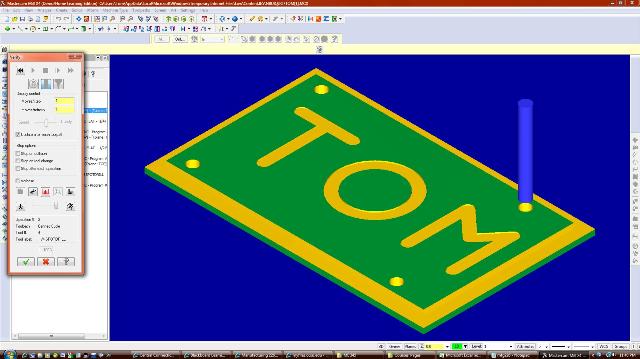

These parts below are exercises produced with Mastercam that could be machined, but were for practice.

Geometry created with CAD part of the program |

Stock created and tool and tool pattern after machining |

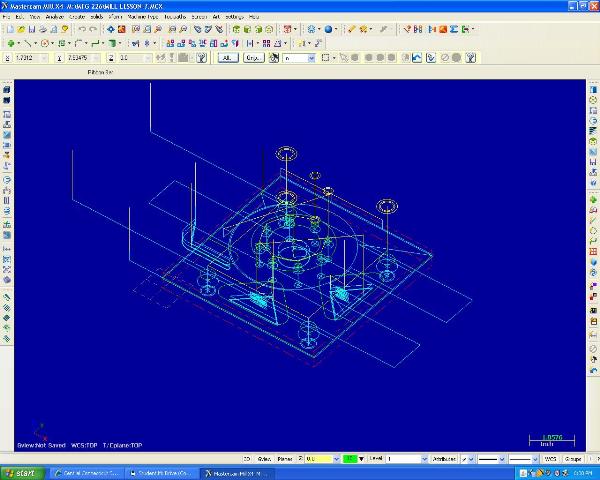

Part shown with tool pattern wireframed above it |

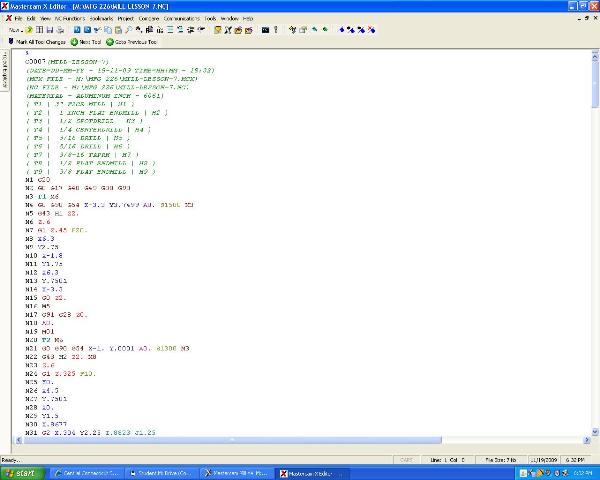

NC code generated from program to be sent to CNC Mill |

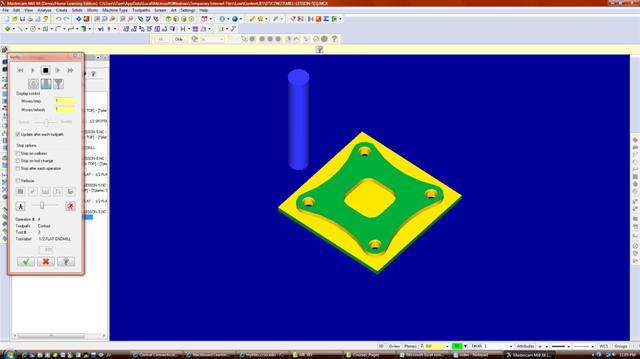

The parts below were created as a 2D drawing and then a piece of 3D stock was created, a tool was assigned and the toolpaths were created. Finally the parts were machined virtually to catch any errors before actually testing

it on a real piece of metal. The first one just had a drill sequence, the second one had a centerdrill sequence, a final drill sequence and then a Milling toolpath to make the pocket and the outside contours,

One of the beginning tutorials |

Another part machined with a Mill |