SolidWorks Ramblings

So, I had previously learned to use the Unigraphics program NX6 to make my CAD models. Since the school had SolidWorks available and I also have a student version copy for my home, I decided to learn it on my own. Considering that most of the industry people I talked to, also used it, knowing it would be a big advantage. I started by making a partition on my hard drive which I loaded Windows XP as this version wouldn't work with my Windows 7 operating system. It would be possible to load it on a virtual machine on my Windows 7 partition, but that would tie up CPU resources to run the VM.

Loading it up, I started by doing some of the tutorials to teach me the basics of the layout. I found this program to be much more intuitive than NX6 and easier to learn, although first learning the more difficult NX6 laid the foundation and taught me the basics of CAD modeling.

I was trying to design a rocket test stand over the weekend to propose to my fellow team members. I figured if I could show them my design, it would be easier to explain it than trying to explain it with no illustrations.

I wanted to have a lower plate that was rigidly mounted and an upper plate that would be supported by two flex beams which would hold the load but flex forward slightly and have no play at right angles to the thrust force.

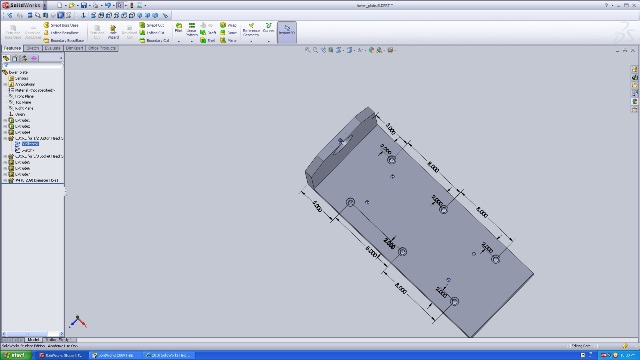

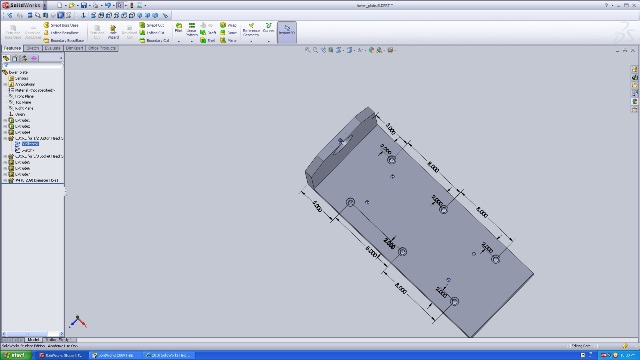

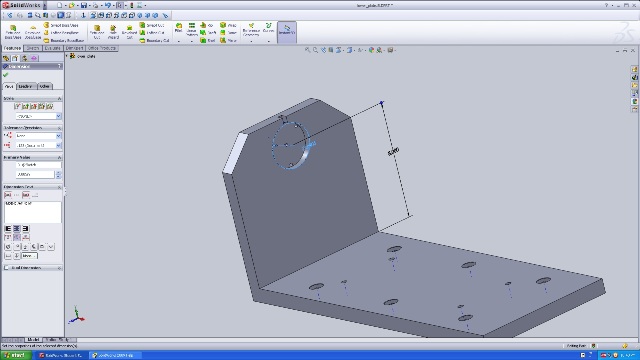

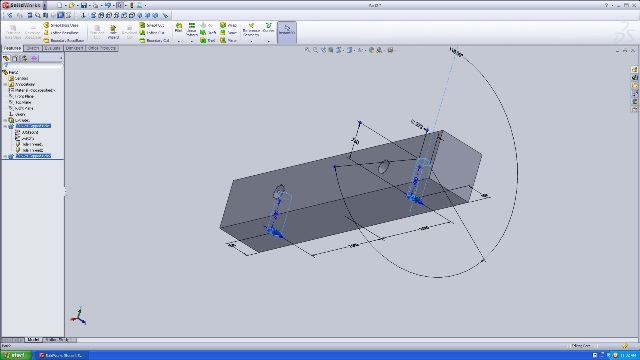

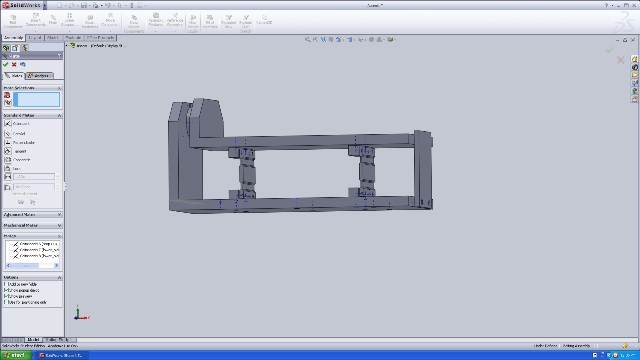

I started by building the lower plate which would serve as the base. |

This plate would rigidly mount to the test bench with cap screws. |

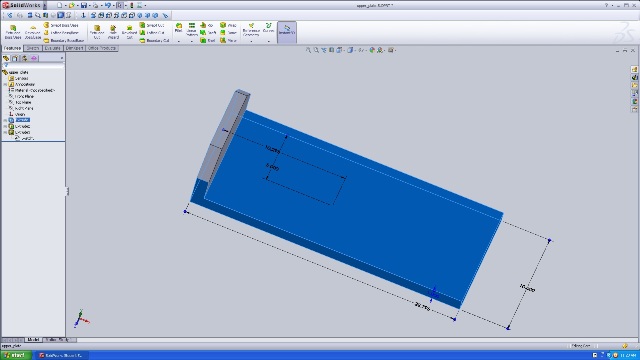

It has a recess to mount a load cell for thrust measurements |

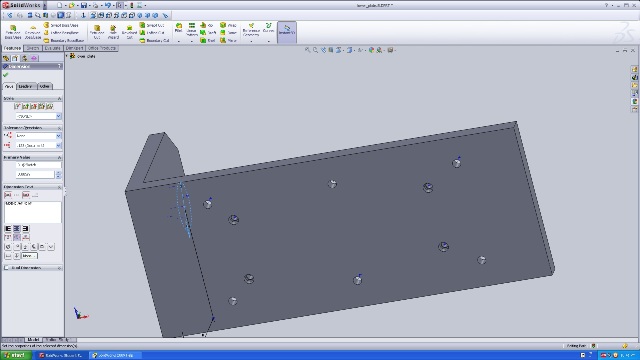

Bottom view |

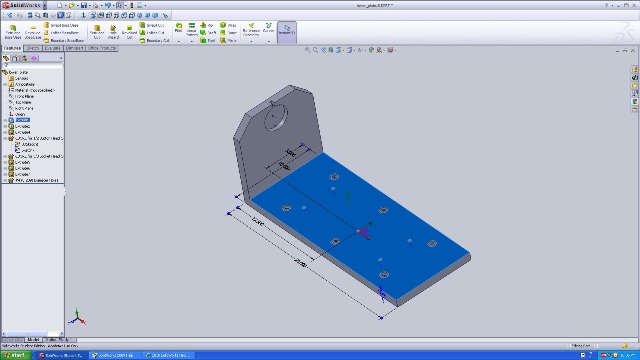

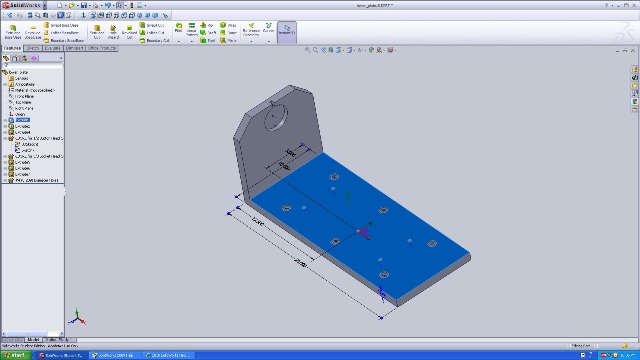

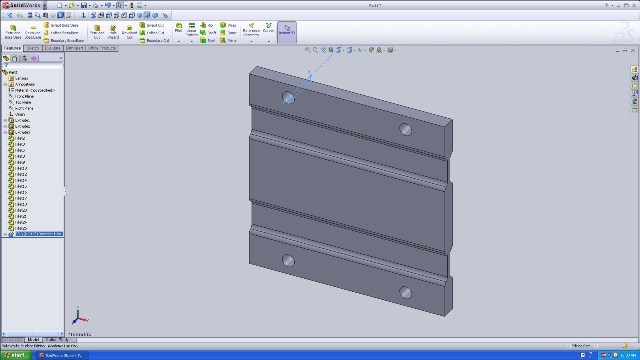

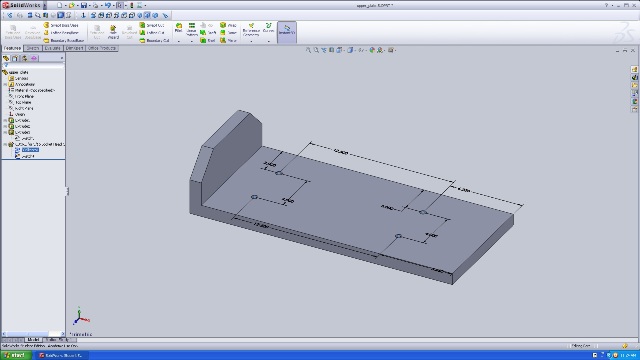

The part below is my unique flex plate which allows forward flex with no lateral movement

It is a wide plate with two webs ground in it with radiuses to eliminate any stress concentrations. |

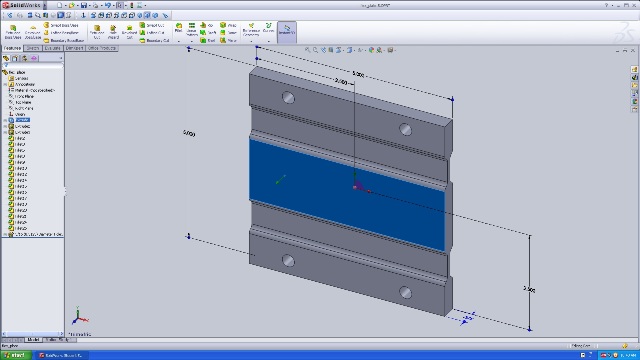

Figured out how to show some dimensions in my pictures |

I then wanted to make some small blocks to attach the flex plates to the stand, an upper plate and assemble it.

One of my blocks, I only have to make one and just add it four times to the final assembly |

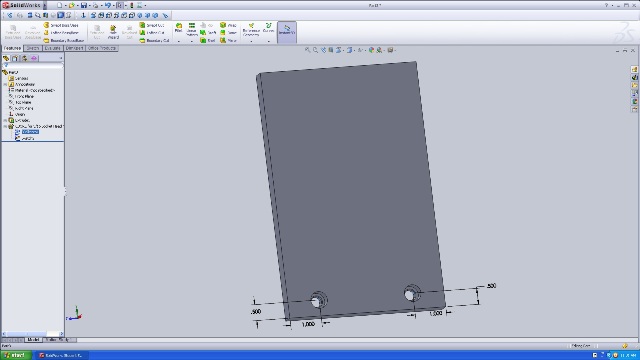

I then made an upper plate where our rocket will be bolted up horizontally |

Added some holes to the plate |

Made a rear stop to limit motion when loading rocket, this could be eliminated with a simple stop screw later on |

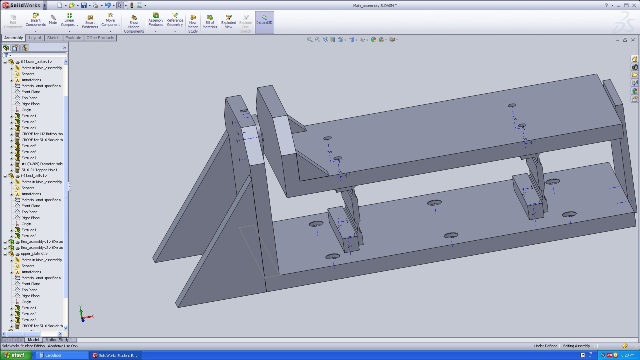

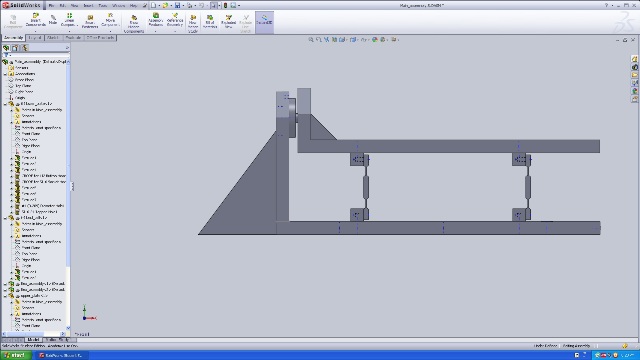

Assembled all parts into my test stand proposal |

Added some gussets to limit flex of base plates |

Adjusted clearances, side view |

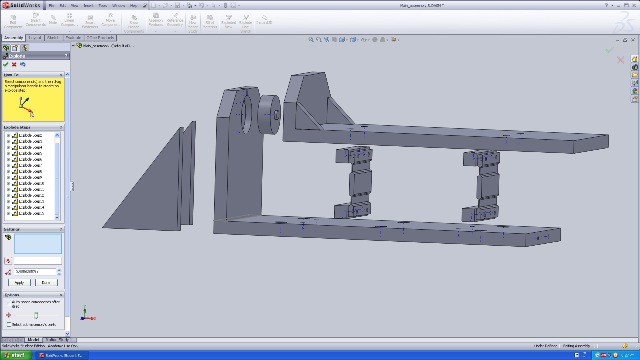

Made exploded view, the round piece is a stiff button load cell shown without wires. |

After spending about 10 hours figuring out this program and design, I'm confident in making most parts with Solidworks. It is a nice program and makes modeling design proposals fairly easy.